Call Us

+86-22-2764-6507

| Availability: | |

|---|---|

Description

KLD200TMT is a smart multi-turn modulating motorized needle valve, designed for highly accurate control of small working stroke equipment and small flow rate water treatment projects,industrial automation equipment. Its main features include an OLED display for clear visibility, convenient and smart menu settings, relay contact alarm output signals, and a position accuracy of ±1% / 0.5%( software adjustable). Powered by a high-performance brushless motor with built-in overcurrent and overload protection, this valve offers reliability and precision in control, very suitable for small flow regulating and high precision regulating applications.

Technical specifications include

Valve Type: Motorized Needle Valve

Sizes: 1/4", 3/8", 1/2", Φ8, Φ10

Pressure: 3000psi (30°C)

Max Angle of Rotation: 360° * n (n<5)

Ambient Temp. : -15°C to 45°C ( can be customized for other temp.)

KLD200TMT is compact, easy-to-operate, and reliable motor-driven. With its excellent performance and comprehensive protection design, it has significant advantages over similar products and fast running and long service life optional.

CE approved.

Applications

Suitable for highly accurate control of small working stroke equipment

Intelligent water-saving control devices, water-saving system executive terminals

Small flow rate water treatment projects

Technical Data

Rated Torque | Nominal Voltage | Max Power | Peak Current@5ms | Wiring | Running Time | Protection Class | Medium Pressure |

15Nm | AC/DC24V | 25W | 1.0A@5ms@DC24V | 4-20mA/0-5V/1-5V/ 0-10V/2-10V/0-20mA | About 24s per circle | IP67 or F Type | 3000psi (30℃) |

AC/DC95-265V | 25W | 0.11A@5ms@AC230V | |||||

20Nm | DC24V | 85W | 3.5A@5ms@DC24V | About 4s per circle |

Main Components Diagram

Main Components

| No. | Components | Material | Qty |

| 1 | Body | 304/ 316L/ 2205 | 1 |

Valve Stem | 304/ 316L/ 2205 | 1 | |

Valve Stem Soft Seat | PCTFE | 1 | |

Valve Stem Packing | PFA/ PTFE | 1 | |

| 2 | Screws | 304 | 4 |

| 3 | Label | PC | 1 |

| 4 | 1.3-inch LCD Screen | OLED | 1 |

| 5 | Buttons | Rubber | 3 |

| 6 | Manual Shaft | 304 | 1 |

| 7 | Manual Shaft Seal | NBR | 1 |

| 8 | Indication Window | Transparent PC | 1 |

| 9 | Upper Cover | PC alloy ※/ die-casting aluminum | 1 |

| 10 | Lower Cover | PC alloy ※/ die-casting aluminum | 1 |

| 11 | Cable Connector | Nylon/nickel-plated brass | 1 |

| ※1 | Hexagonal Wrench Bracket | Heat-resistant ABS | 1 |

| ※2 | Hexagonal Wrench | Tool steel | 1 |

※ Avoid direct or indirect contact between PC and organic solvents such as toluene, xylene, ketones, dichloromethane, trichloromethane, and chloroform ect., due to corrosion resistance characteristics of PC materials.

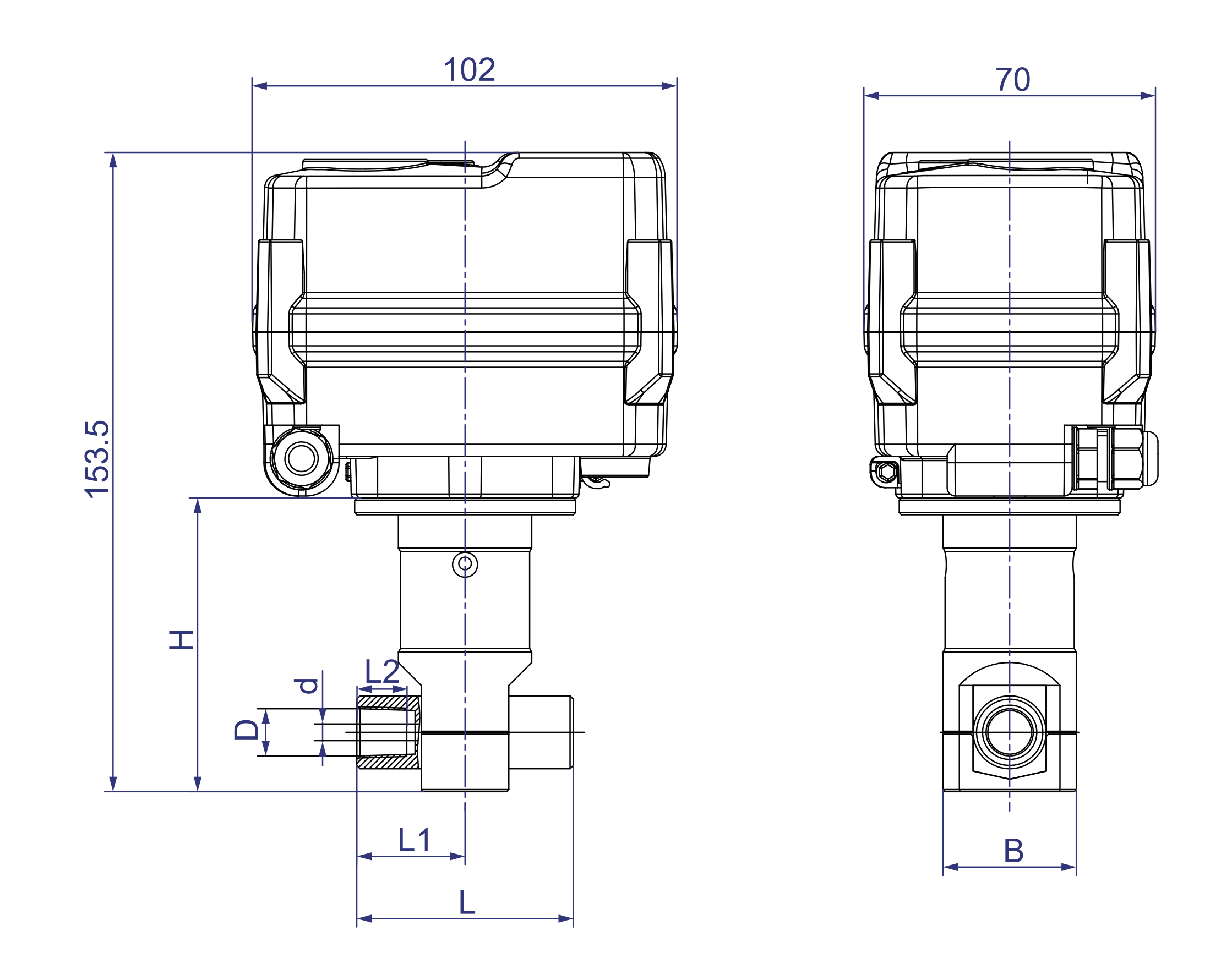

Dimensions [1/4"-1/2", Thread]

Dimensions (mm)

Size | L | L1 | L2 | D | H | B | d | W (kg) |

1/4" | 52 | 26 | 11 | NPT 1/4" | 70.5 ± 1 | Φ32 | 4 | - |

3/8" | 67 | 33.5 | 10.5 | G 3/8" | 70.5 ± 1 | Φ32 | 2 | - |

1/2" | 70 | 35 | 12 | G 1/2" | 70.5 ± 1 | Φ32 | 2 | - |

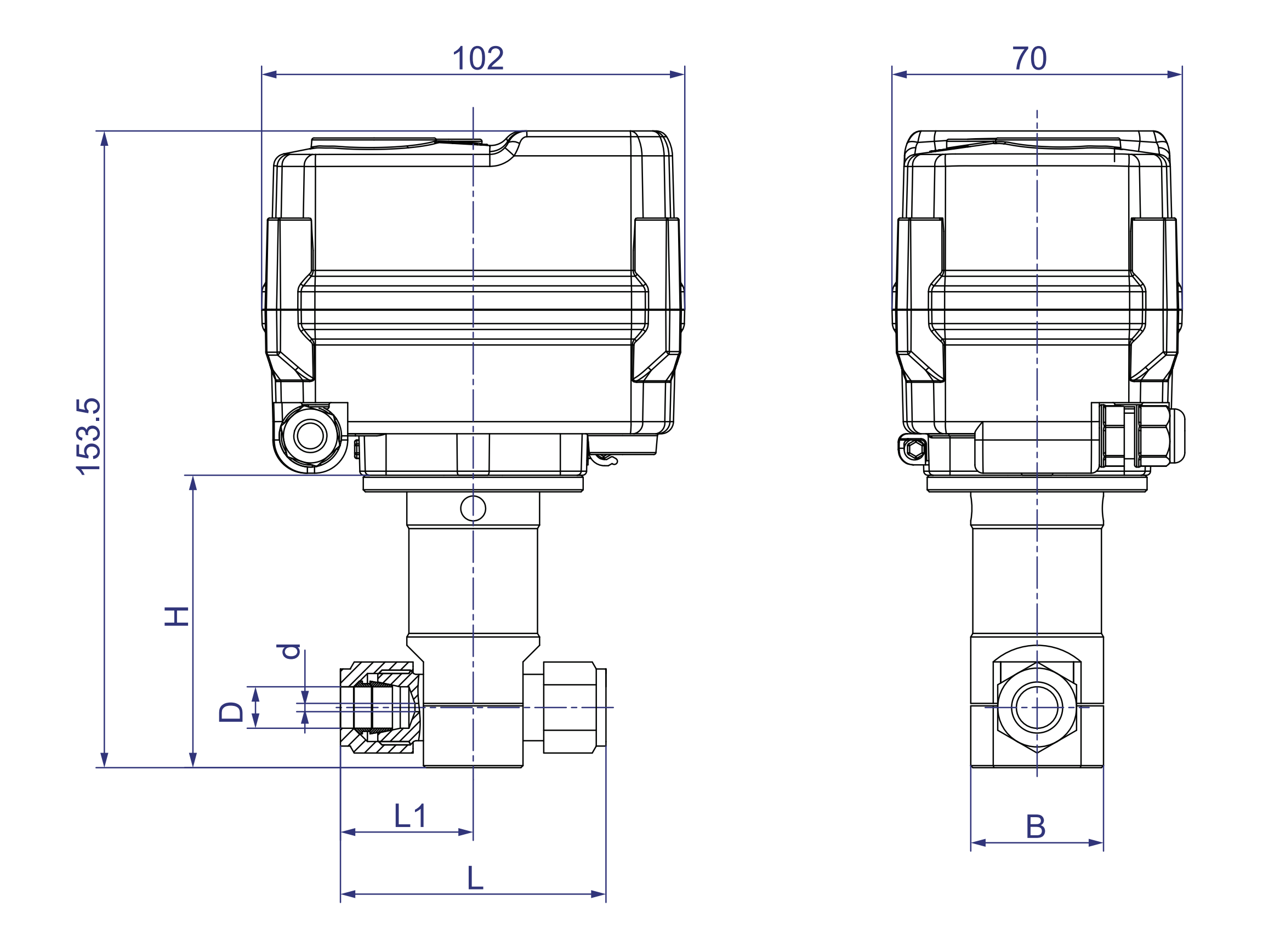

Dimensions [Φ8-Φ10, Swivel Nut]

Dimensions (mm)

Size | L | L1 | D | H | B | d | W (kg) |

Φ8 | 60 | 30 | Φ8 | 70.5±1 | Φ32 | 2 | - |

Φ10 | 64 | 32 | Φ10 | 70.5±1 | Φ32 | 2 | - |

Notes: L is the dimension when the flange nut is tightened by hand.It is only for preliminary selection, please contact KLD for final confirmation on product details such as dimensions, parameters etc.

Imporant notice when selecting modulating valve:It is not recommended to cut off frequently, as the function of modulating valve is to precisely regulate the fluid flow rate.Ball valve or global valve is recommended if used for shut off function.

Flow Coefficient

Functional Data

Angle of Rotation | 360° * n (n<5) |

Degree of Protection | IP67 As Per En60529/GB4208-2008 (all directions) F type [damp-proof,adding dehumidifying heater] |

Manual Override | Matching hexagon wrench (only using at no power) |

| Position Indicator |

and OLED |

Working Conditions

Ambient Temp. | -15℃<t<45℃ |

| Ambient Humidity | 5-95%RH, non-condensing |

※Subject to technical changes

Description

KLD200TMT is a smart multi-turn modulating motorized needle valve, designed for highly accurate control of small working stroke equipment and small flow rate water treatment projects,industrial automation equipment. Its main features include an OLED display for clear visibility, convenient and smart menu settings, relay contact alarm output signals, and a position accuracy of ±1% / 0.5%( software adjustable). Powered by a high-performance brushless motor with built-in overcurrent and overload protection, this valve offers reliability and precision in control, very suitable for small flow regulating and high precision regulating applications.

Technical specifications include

Valve Type: Motorized Needle Valve

Sizes: 1/4", 3/8", 1/2", Φ8, Φ10

Pressure: 3000psi (30°C)

Max Angle of Rotation: 360° * n (n<5)

Ambient Temp. : -15°C to 45°C ( can be customized for other temp.)

KLD200TMT is compact, easy-to-operate, and reliable motor-driven. With its excellent performance and comprehensive protection design, it has significant advantages over similar products and fast running and long service life optional.

CE approved.

Applications

Suitable for highly accurate control of small working stroke equipment

Intelligent water-saving control devices, water-saving system executive terminals

Small flow rate water treatment projects

Technical Data

Rated Torque | Nominal Voltage | Max Power | Peak Current@5ms | Wiring | Running Time | Protection Class | Medium Pressure |

15Nm | AC/DC24V | 25W | 1.0A@5ms@DC24V | 4-20mA/0-5V/1-5V/ 0-10V/2-10V/0-20mA | About 24s per circle | IP67 or F Type | 3000psi (30℃) |

AC/DC95-265V | 25W | 0.11A@5ms@AC230V | |||||

20Nm | DC24V | 85W | 3.5A@5ms@DC24V | About 4s per circle |

Main Components Diagram

Main Components

| No. | Components | Material | Qty |

| 1 | Body | 304/ 316L/ 2205 | 1 |

Valve Stem | 304/ 316L/ 2205 | 1 | |

Valve Stem Soft Seat | PCTFE | 1 | |

Valve Stem Packing | PFA/ PTFE | 1 | |

| 2 | Screws | 304 | 4 |

| 3 | Label | PC | 1 |

| 4 | 1.3-inch LCD Screen | OLED | 1 |

| 5 | Buttons | Rubber | 3 |

| 6 | Manual Shaft | 304 | 1 |

| 7 | Manual Shaft Seal | NBR | 1 |

| 8 | Indication Window | Transparent PC | 1 |

| 9 | Upper Cover | PC alloy ※/ die-casting aluminum | 1 |

| 10 | Lower Cover | PC alloy ※/ die-casting aluminum | 1 |

| 11 | Cable Connector | Nylon/nickel-plated brass | 1 |

| ※1 | Hexagonal Wrench Bracket | Heat-resistant ABS | 1 |

| ※2 | Hexagonal Wrench | Tool steel | 1 |

※ Avoid direct or indirect contact between PC and organic solvents such as toluene, xylene, ketones, dichloromethane, trichloromethane, and chloroform ect., due to corrosion resistance characteristics of PC materials.

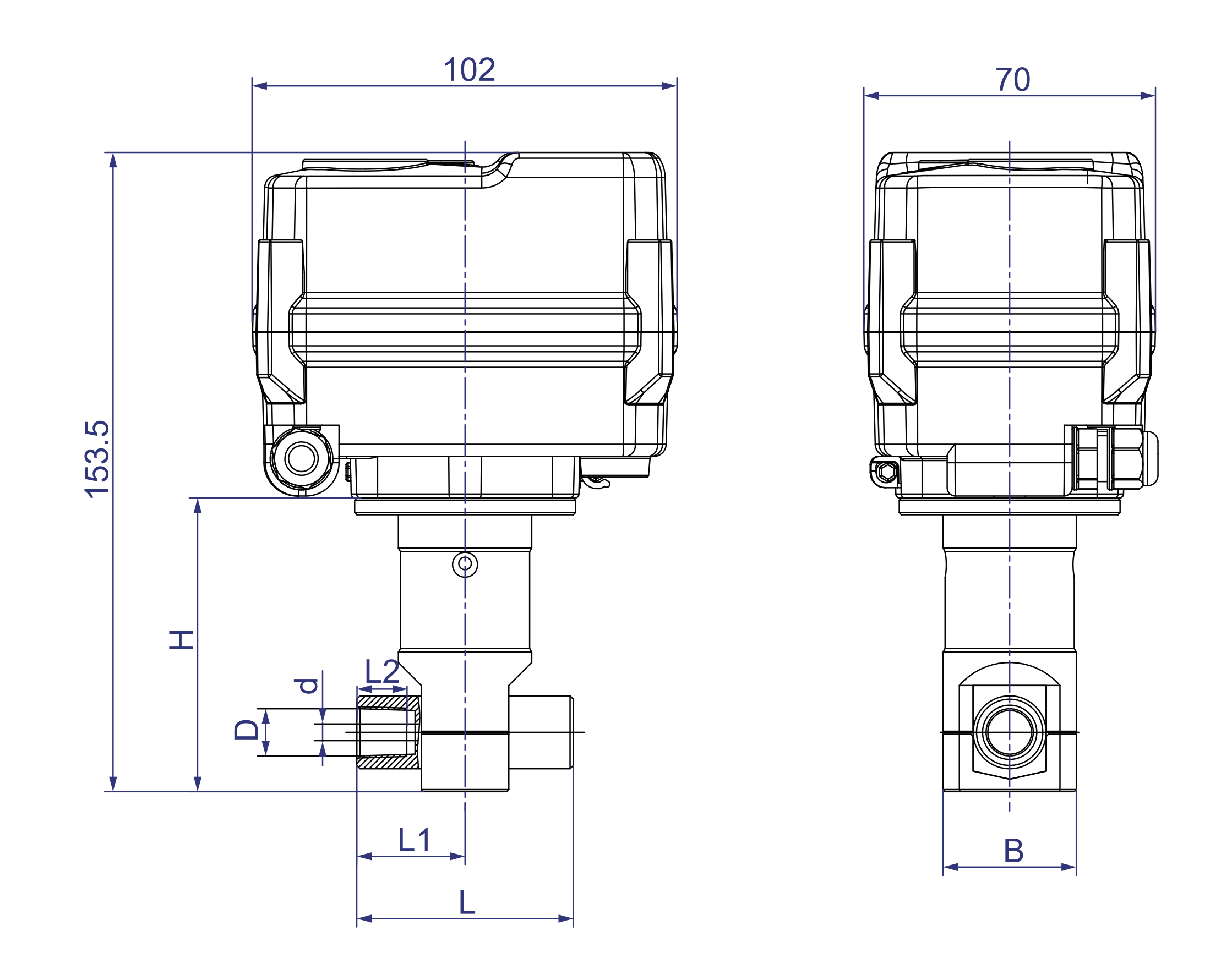

Dimensions [1/4"-1/2", Thread]

Dimensions (mm)

Size | L | L1 | L2 | D | H | B | d | W (kg) |

1/4" | 52 | 26 | 11 | NPT 1/4" | 70.5 ± 1 | Φ32 | 4 | - |

3/8" | 67 | 33.5 | 10.5 | G 3/8" | 70.5 ± 1 | Φ32 | 2 | - |

1/2" | 70 | 35 | 12 | G 1/2" | 70.5 ± 1 | Φ32 | 2 | - |

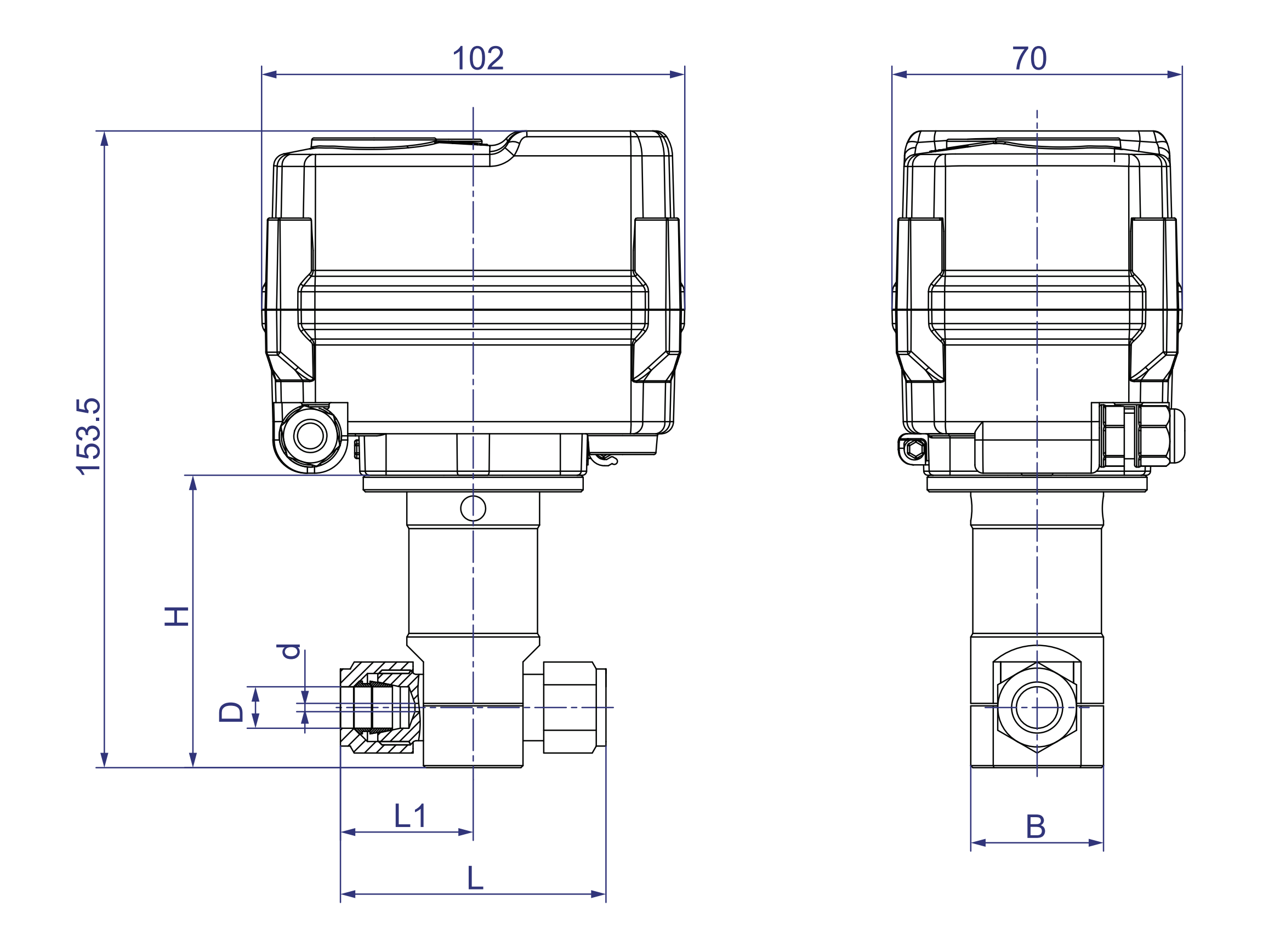

Dimensions [Φ8-Φ10, Swivel Nut]

Dimensions (mm)

Size | L | L1 | D | H | B | d | W (kg) |

Φ8 | 60 | 30 | Φ8 | 70.5±1 | Φ32 | 2 | - |

Φ10 | 64 | 32 | Φ10 | 70.5±1 | Φ32 | 2 | - |

Notes: L is the dimension when the flange nut is tightened by hand.It is only for preliminary selection, please contact KLD for final confirmation on product details such as dimensions, parameters etc.

Imporant notice when selecting modulating valve:It is not recommended to cut off frequently, as the function of modulating valve is to precisely regulate the fluid flow rate.Ball valve or global valve is recommended if used for shut off function.

Flow Coefficient

Functional Data

Angle of Rotation | 360° * n (n<5) |

Degree of Protection | IP67 As Per En60529/GB4208-2008 (all directions) F type [damp-proof,adding dehumidifying heater] |

Manual Override | Matching hexagon wrench (only using at no power) |

| Position Indicator |

and OLED |

Working Conditions

Ambient Temp. | -15℃<t<45℃ |

| Ambient Humidity | 5-95%RH, non-condensing |

※Subject to technical changes