Call Us

+86-22-2764-6507

| Availability: | |

|---|---|

Description

Technical specifications include

Valve Type: Three-way plastic ball valve

Sizes: DN15, DN20

Pressure: Maximum 1.0 MPa (PN10)

Flow: Varies with valve size and application

Medium Temperature: 0°C to 90°C

Ambient Temperature: -20°C to 45°C

The KLD20S series valve is suitable for a wide range of applications, including environmental protection systems, water treatment systems (e.g., ClO₂, O₃ systems), small industrial automation equipment, and other corrosive media applications such as acid and alkali handling. It provides a reliable alternative to solenoid valves, particularly when solenoid valves may not operate reliably. The valve's modular design and optional configurations (e.g., different wiring options) allow for customization to meet specific application requirements.

CE approved

Applications

Used for corrosive medium such as acid and alkali,etc

Replacing solenoid valve, particularly when solenoid valve cannot work reliably

Environmental protection,water treatment system

Small industrial automation equipment

Excellent in ClO2,O3 system

Technical Parameters

| Series | Manual Override | Max Torque | Operating | Working Voltage | Max Power | Enclosure | Max Pressure | Medium Temperature | Ambient Temperature | Humidity | ||

| KLD20S | yes | 2N.m | about 5s | DC5V, 12V | 3W | IP67 | 1.0Mpa | 0-90°C | -20°C< t<45°C | ≤85% non-condensing | ||

| AC/DC 12V, 24V | 4W/ 5W@KT | |||||||||||

| KLD20SJ | no | AC/DC110V, 220V | 5W/ 8W@KT | |||||||||

Main Components Diagram

Main Components

Parts | Material |

Actuator housing | PC alloy ※1 |

Valve body | CPVC, PVDF |

Valve ball | CPVC, PVDF |

Stem | CPVC, PVDF |

Ball seat | PTFE |

| Seal | FPM, EPDM, NBR |

Dimension

KLD20S |

KLD20SJ |

Connection Size(unit:mm)

| DN | G1 | L1=L2 | L | L4 | d | F | H1 | H2 | H | W(kg) | |||||

| thread | socket | thread | socket | thread | socket | thread | socket | 20S | 20SJ | ||||||

| DN15 | G1/2" or NPT1/2" | 20.3(external diameter) | 18.0 | 18.0 | 101.0 | 101.0 | 73.5 | 73.5 | 12.0 | 46.0 | 23.0 | 24.25 | 107.0 | 103.5 | - |

| DN20 | G3/4" or NPT3/4" | 25.3(external diameter) | 18.0 | 18.0 | 101.0 | 101.0 | 73.5 | 73.5 | 12.0 | 46.0 | 23.0 | 24.25 | 107.0 | 103.5 | - |

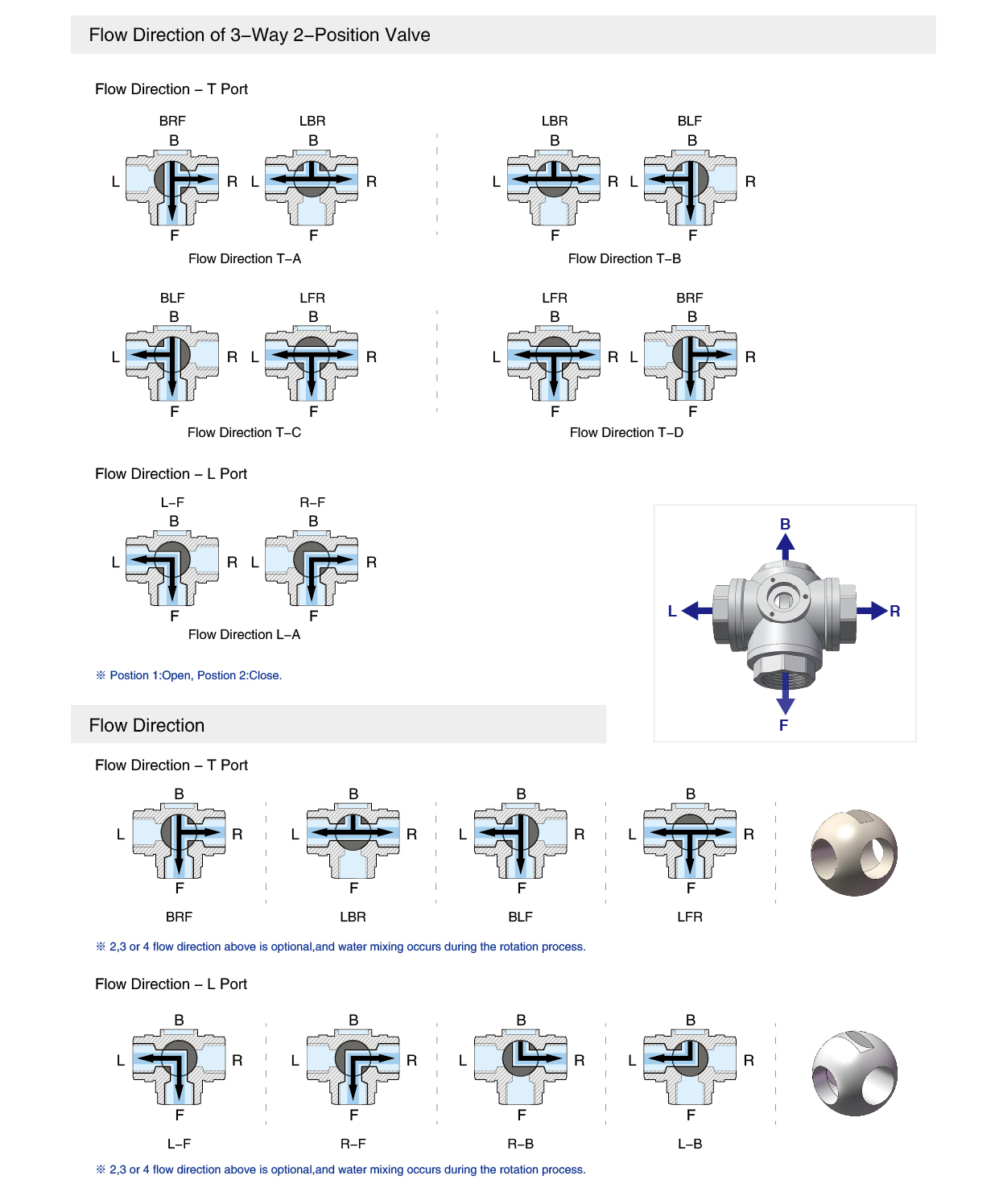

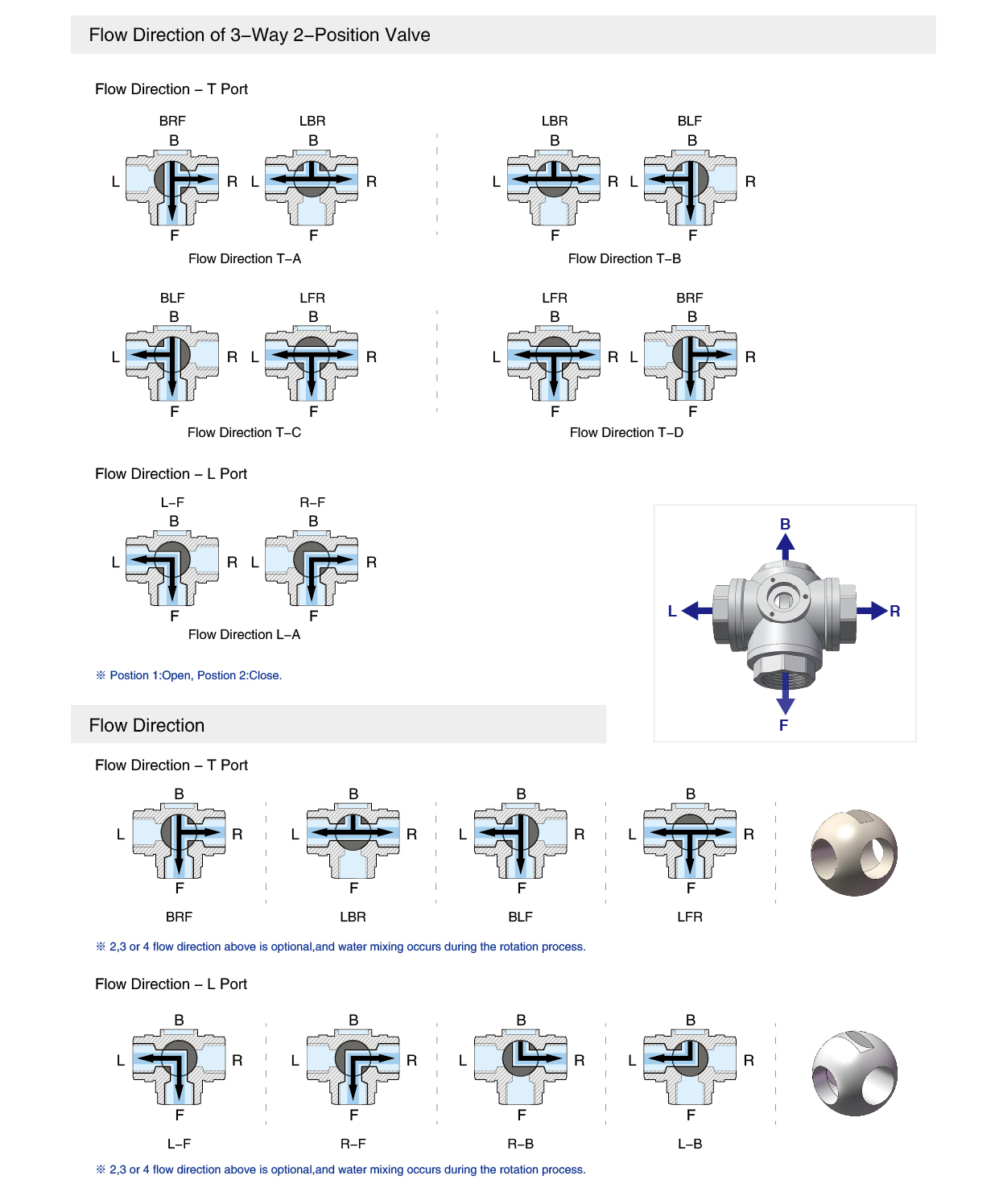

Flow Direction

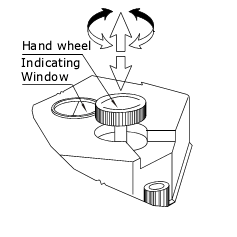

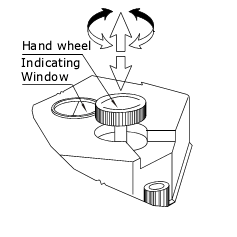

Instructions for Manual Override

It is only permitted to use when power is cut.

Lift the hand-wheel, and turn it left or right until the valve is in place.

Press down hand-wheel after using manual override in order to work properly when power is supplied.

Wiring

B2, B3, BD3,KT2 are available.We can accept feedback customization.Please contact sales for more details.

The service life is the testing data in the condition of 1.0Mpa, 200L/h, tap water as working medium. Different working occasions will influence the service life.

KLD20S has manual override; KLD20J does not have manual override, other parameters are the same as KLD20S.

Actuators are not direct-mount-on. Actuators are not recommended to be sold separately.

The pressure is tested under one-way direction.

※1 Avoid direct or indirect contact between PC and organic solvents such as toluene, xylene, ketones, dichloromethane, trichloromethane, and chloroform ect., due to corrosion resistance characteristics of PC materials.

※Subject to technical changes

Description

Technical specifications include

Valve Type: Three-way plastic ball valve

Sizes: DN15, DN20

Pressure: Maximum 1.0 MPa (PN10)

Flow: Varies with valve size and application

Medium Temperature: 0°C to 90°C

Ambient Temperature: -20°C to 45°C

The KLD20S series valve is suitable for a wide range of applications, including environmental protection systems, water treatment systems (e.g., ClO₂, O₃ systems), small industrial automation equipment, and other corrosive media applications such as acid and alkali handling. It provides a reliable alternative to solenoid valves, particularly when solenoid valves may not operate reliably. The valve's modular design and optional configurations (e.g., different wiring options) allow for customization to meet specific application requirements.

CE approved

Applications

Used for corrosive medium such as acid and alkali,etc

Replacing solenoid valve, particularly when solenoid valve cannot work reliably

Environmental protection,water treatment system

Small industrial automation equipment

Excellent in ClO2,O3 system

Technical Parameters

| Series | Manual Override | Max Torque | Operating | Working Voltage | Max Power | Enclosure | Max Pressure | Medium Temperature | Ambient Temperature | Humidity | ||

| KLD20S | yes | 2N.m | about 5s | DC5V, 12V | 3W | IP67 | 1.0Mpa | 0-90°C | -20°C< t<45°C | ≤85% non-condensing | ||

| AC/DC 12V, 24V | 4W/ 5W@KT | |||||||||||

| KLD20SJ | no | AC/DC110V, 220V | 5W/ 8W@KT | |||||||||

Main Components Diagram

Main Components

Parts | Material |

Actuator housing | PC alloy ※1 |

Valve body | CPVC, PVDF |

Valve ball | CPVC, PVDF |

Stem | CPVC, PVDF |

Ball seat | PTFE |

| Seal | FPM, EPDM, NBR |

Dimension

KLD20S |

KLD20SJ |

Connection Size(unit:mm)

| DN | G1 | L1=L2 | L | L4 | d | F | H1 | H2 | H | W(kg) | |||||

| thread | socket | thread | socket | thread | socket | thread | socket | 20S | 20SJ | ||||||

| DN15 | G1/2" or NPT1/2" | 20.3(external diameter) | 18.0 | 18.0 | 101.0 | 101.0 | 73.5 | 73.5 | 12.0 | 46.0 | 23.0 | 24.25 | 107.0 | 103.5 | - |

| DN20 | G3/4" or NPT3/4" | 25.3(external diameter) | 18.0 | 18.0 | 101.0 | 101.0 | 73.5 | 73.5 | 12.0 | 46.0 | 23.0 | 24.25 | 107.0 | 103.5 | - |

Flow Direction

Instructions for Manual Override

It is only permitted to use when power is cut.

Lift the hand-wheel, and turn it left or right until the valve is in place.

Press down hand-wheel after using manual override in order to work properly when power is supplied.

Wiring

B2, B3, BD3,KT2 are available.We can accept feedback customization.Please contact sales for more details.

The service life is the testing data in the condition of 1.0Mpa, 200L/h, tap water as working medium. Different working occasions will influence the service life.

KLD20S has manual override; KLD20J does not have manual override, other parameters are the same as KLD20S.

Actuators are not direct-mount-on. Actuators are not recommended to be sold separately.

The pressure is tested under one-way direction.

※1 Avoid direct or indirect contact between PC and organic solvents such as toluene, xylene, ketones, dichloromethane, trichloromethane, and chloroform ect., due to corrosion resistance characteristics of PC materials.

※Subject to technical changes